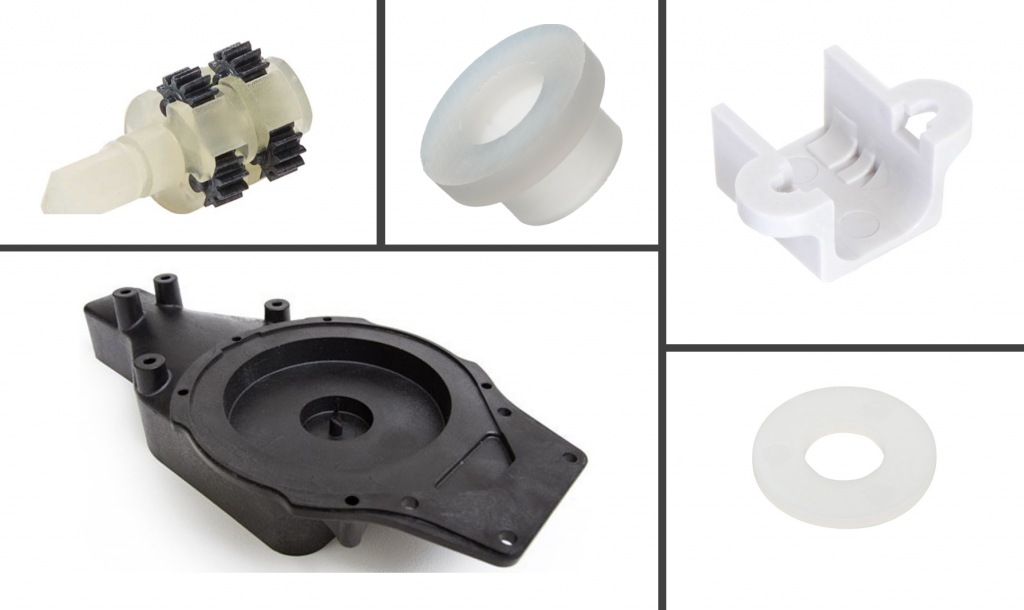

Plastic Injection Parts

The needs of our customers provide us with opportunities to create a range of components for any insert molding projects you may have. From plastic prototyping to production molding, Huayan Tech’s custom injection molding service is ideal for the manufacturing of competitive pricing, high-quality molded parts in a fast lead time.

We work with a wide variety of thermoplastic polymers, elastomers, and resins to create the perfect injection molded parts for your needs. Our expertise with standard specialized materials and exotic resins enables us to produce plastic injection molded parts and components to match the precise specifications of any project. While the material is strong, it also produces low waste, making our services highly sustainable.

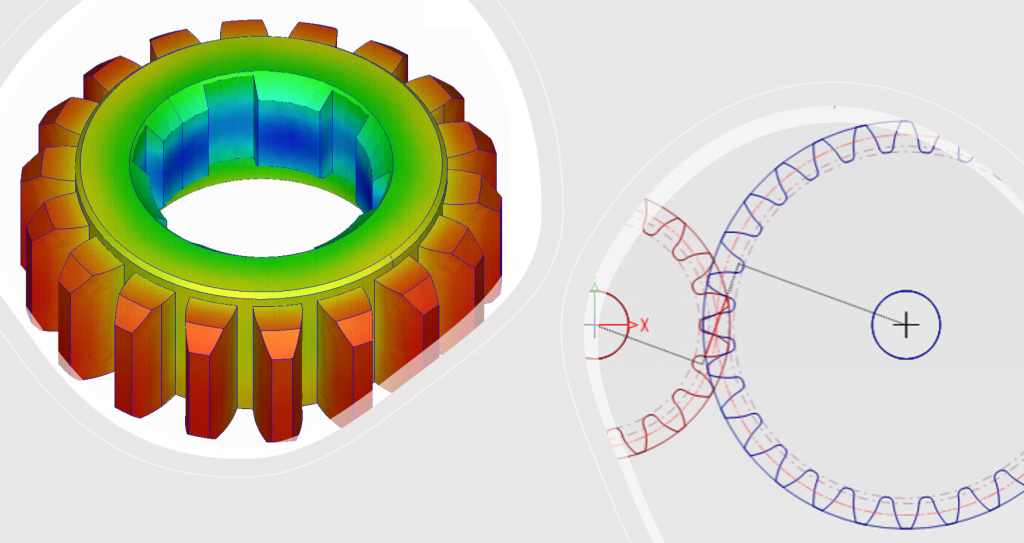

Although we are not solely limited to polymer gears, we take pride in producing reliable miniature motion products around the world each day. With sophisticated processes and a highly skilled engineering team, we have over 10 years of experience in specialized gear tooling and production process implementation for performance optimization and moldability. Our team leverages gear design software and focuses on no mesh interference to avoid binding, adequate contact ratio to minimize noise, teeth designed specifically for the application, and meshing teeth balanced for tooth strength and minimal wear.

Today, Huayan Tech designs, engineers and delivers far more than custom plastic gears alone. To deliver customer value and meet today’s fast-moving, lean market needs, we also design, engineer and build complete plastic injection molded and electromechanical assemblies.

Some of the materials we mold include POM, Nylon and PEEK. Some of the most common types of gears that we produce include spur, helical, bevel, worm and ring gear. By configuring our plastic injection molding equipment, process and workflow and a highly trained team, Huayan Tech helps customers produce better complete products with fewer vendors and greater efficiency.

We offer a complete injection molding solution with an in-house Technical Services team that supports clients with material selection by application, part design assistance to optimize manufacturing costs and part performance, injection mold / tooling design, value engineering, mold flow analysis, and finite element analysis.

Over the years, best practices for tooling and part manufacturing have changed substantially. While production checklists are still critical components of the process, the work that happens earlier in the development cycle is what creates real efficiencies in regard to time and budget. When a tool-maker / injection molder is involved early in the development cycle, customer objectives are understood and unexpected surprises are avoided.

Are you looking for an injection molding that can provide expert consultation from design to production completion? Connect with our dedicated team for manufacturability, development, and production.