Linear Gearheads

We provides linear motion solution with both stepper motors and spur geared motors integrated with lead screws. Lead screws have relatively straight-forward geometry and performance and offer the flexibility to be adapted to the needs of most applications. While there are many applications that require the high stiffness, thrust capacity and absolute accuracy of ball screws, in many cases lead screws can be engineered to meet performance requirements and provide advantages over a ball screw at a substantially lower cost.

Huayan Tech offers a unique line of stepper motor linear actuators that opens new avenues for equipment designers who require high performance and exceptional endurance in a very small package. This allows the stepper motor linear actuator to provide quiet, efficient, durable and cost-effective linear motion solutions. For higher efficiency and extreme long life and high precision applications, Huayan Tech also provides the stepper motor linear actuator with different grade of ball screw at reasonable cost.

These stepper motor linear actuators are ideal for applications requiring a combination of precise positioning, rapid motion and long life. Typical applications include X-Y tables, medical equipment, semiconductor handling, telecommunications equipment, valve control, and numerous other uses.

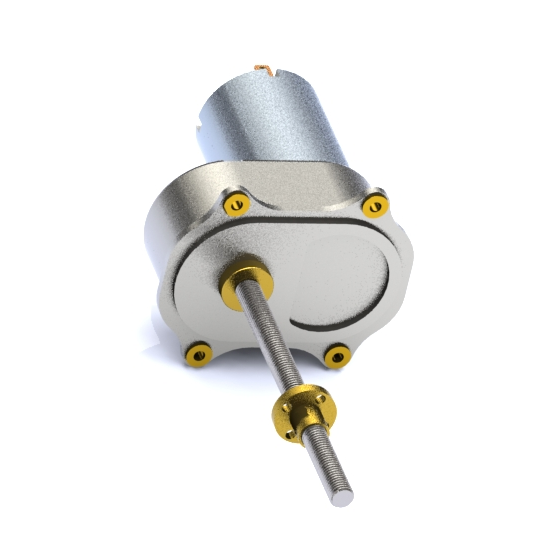

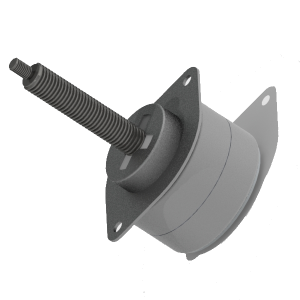

Besides stepper motor linear actuators, we also offer linear motion solution with spur gear motors. Where a lead screw is driven as an indirect drive, through a coupling, our complete range of DC motors and gearheads is available. For linear drives when stroke length is below 100mm and thrust does not exceed 50N, both SG1000 and SG2000 series gearmotors are compatible with lead screw and can be converted into linear motion gearheads. A lead screw can be substituted for the output shaft. V-thread and trapezoidal thread are both available, in a range of pitches.

A variety of customizations are available upon to request, such as different screw length, special design nut, anti-backlash nut, safety brake, encoder, etc.

The complex design issues associated with the conversion of rotary to linear motion is an area of special expertise; if you need support, please give us a call.